Prefabricated Homes – Affordable and Efficient Housing Options with Fast Installation

Prefabricated homes represent a revolutionary approach to residential construction, offering homeowners a faster, more cost-effective alternative to traditional building methods. These factory-built structures combine quality craftsmanship with streamlined production processes, delivering complete housing solutions that can be assembled on-site in a fraction of the time required for conventional construction.

The housing landscape in Canada has shifted dramatically in recent years, with more buyers and builders exploring alternatives to conventional construction methods. Prefabricated homes represent a growing segment of the residential market, offering streamlined processes and potentially lower overall costs. Understanding how these structures work, what designs are available, and how they compare to traditional builds can help prospective homeowners make informed decisions about their housing investments.

What Are Prefabricated Homes and How Do They Work?

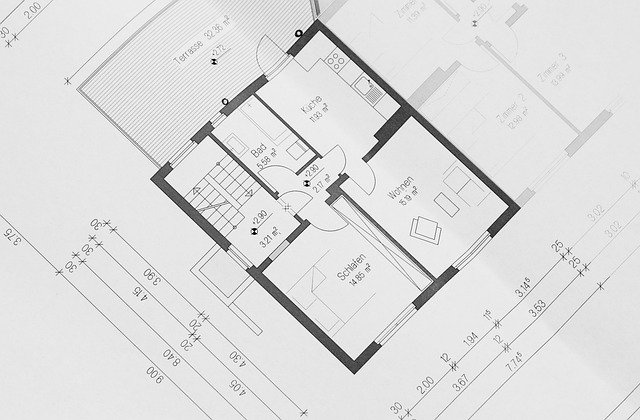

Prefabricated homes are residential structures with components manufactured in a controlled factory setting before being transported to the building site for assembly. Unlike traditional construction where materials arrive separately and assembly happens entirely on-site, prefab homes arrive in sections or modules that are substantially complete. The manufacturing process occurs indoors, protecting materials from weather exposure and allowing for precise quality control. Once sections are ready, they are transported by truck to the prepared foundation site where crews connect utilities, seal joints, and complete finishing touches. The entire process typically takes weeks rather than months, significantly reducing construction timelines. Factory construction also minimizes material waste and allows for bulk purchasing of supplies, contributing to cost efficiencies that benefit buyers.

How Do Efficient Prefabricated Homes Compare to Traditional Construction?

When comparing prefabricated homes to traditional stick-built houses, several factors distinguish the two approaches. Construction time represents one of the most significant differences, with prefab homes often ready for occupancy in two to four months compared to six months to over a year for traditional builds. Weather delays affect traditional construction more severely since most work happens outdoors, while factory-built components face minimal weather-related setbacks. Quality control in prefab manufacturing tends to be more consistent due to standardized processes and controlled environments. However, traditional construction offers greater flexibility for mid-project design changes, whereas prefab homes require more upfront planning since modifications become difficult once manufacturing begins. Site preparation requirements are similar for both methods, requiring proper foundations and utility connections. Energy efficiency often favors prefab homes due to tighter construction tolerances achieved in factory settings, potentially leading to lower heating and cooling costs over time. Transportation logistics present unique challenges for prefab homes, particularly in remote areas where delivery costs can increase substantially.

What Types of Prefabricated Home Designs Are Available?

The prefabricated housing market offers diverse design options to suit various preferences and needs. Modular homes consist of multiple factory-built sections transported separately and assembled on-site, allowing for multi-story designs and larger floor plans. Panelized homes arrive as wall panels, roof trusses, and floor systems that crews assemble on prepared foundations, offering flexibility in layout while maintaining factory precision. Manufactured homes, built entirely in factories on permanent steel chassis, represent the most affordable prefab option and must meet specific federal building codes. Tiny homes have gained popularity as compact, efficient living spaces often built on trailers for mobility or permanent foundations for stationary placement. Contemporary designs now include modern aesthetics with open floor plans, large windows, and sustainable materials, moving beyond outdated perceptions of prefab housing. Traditional styles remain available for those preferring classic architectural elements like pitched roofs, covered porches, and conventional exteriors. Customization levels vary by manufacturer, with some offering extensive personalization of finishes, layouts, and features, while others provide limited modification options to maintain cost efficiencies.

How Do Zoning Laws and Building Codes Affect Prefab Installation?

Navigating regulatory requirements represents a critical step in prefab home installation across Canada. Provincial and municipal building codes govern construction standards, and prefabricated homes must meet the same structural, electrical, plumbing, and safety requirements as traditional builds. Zoning regulations determine where homes can be placed, minimum lot sizes, setback requirements from property lines, and permitted building heights. Some municipalities have specific restrictions on manufactured homes or require them to be placed only in designated communities. Building permits are required regardless of construction method, and inspections occur at various stages including foundation, electrical, plumbing, and final occupancy. Manufacturers typically design homes to meet national building codes, but buyers must verify compliance with local amendments and requirements. Foundation specifications vary by region based on soil conditions and frost depth, affecting preparation costs and timelines. Septic and well requirements in rural areas add complexity and expense compared to urban locations with municipal services. Homeowners associations may impose additional restrictions on home appearance, materials, or placement that could limit prefab options in certain neighborhoods.

Real-World Cost Insights for Prefabricated Homes

Understanding the financial aspects of prefabricated homes helps buyers budget appropriately and compare options effectively. Base prices for prefab homes in Canada typically range from CAD 150 to CAD 400 per square foot depending on design complexity, finishes, and manufacturer. A modest 1,200 square foot modular home might cost between CAD 180,000 and CAD 300,000 for the structure itself, while larger custom designs can exceed CAD 500,000. These figures represent the home only and do not include land purchase, site preparation, foundation work, utility connections, permits, transportation, or installation labor. Site preparation costs vary widely based on location and existing conditions, potentially adding CAD 20,000 to CAD 80,000 or more for excavation, foundation, and service connections. Transportation expenses depend on distance from the manufacturing facility, with deliveries within 200 kilometers typically costing CAD 5,000 to CAD 15,000, while remote locations may face significantly higher charges. Installation and finishing work generally adds CAD 30,000 to CAD 100,000 depending on complexity and local labor rates.

| Home Type | Typical Size Range | Estimated Cost Range (Structure Only) |

|---|---|---|

| Manufactured Home | 600-1,800 sq ft | CAD 90,000 - CAD 250,000 |

| Modular Home | 1,000-3,000 sq ft | CAD 180,000 - CAD 600,000 |

| Panelized Home | 1,200-2,500 sq ft | CAD 200,000 - CAD 500,000 |

| Tiny Home | 200-600 sq ft | CAD 40,000 - CAD 120,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Total project costs including land, site work, and all installation expenses typically range from CAD 250,000 to CAD 800,000 or more for completed prefab homes in Canada. Financing options include traditional mortgages, though some lenders have specific requirements for prefab homes, particularly manufactured homes on leased land. Comparing quotes from multiple manufacturers and obtaining detailed breakdowns of included features helps buyers understand true costs and avoid unexpected expenses. Long-term value considerations include energy efficiency, maintenance requirements, and resale potential, which can vary based on construction quality and local market perceptions of prefab housing.

Prefabricated homes continue evolving as viable housing solutions for Canadians seeking efficiency, quality, and value. By understanding construction methods, available designs, regulatory requirements, and realistic cost expectations, prospective buyers can determine whether prefab housing aligns with their needs and circumstances. Thorough research, careful planning, and working with reputable manufacturers and builders remain essential steps toward successful prefab home ownership.