Prefabricated Homes in Canada: 2026 Guide to Options, Pricing, and Hidden Costs

Prefabricated homes in Canada have evolved from basic modular units into advanced housing solutions that combine efficiency, sustainability, and contemporary design. As construction costs continue to rise and housing shortages persist across many Canadian provinces, more homebuyers are turning to prefabricated housing as a practical alternative to traditional site-built homes. This comprehensive guide explores construction methods, market trends, design options, and realistic cost expectations for prefabricated homes in Canada in 2026, helping you make informed decisions in a rapidly growing segment of the housing market.

Prefabricated housing represents a practical alternative to traditional site-built construction, combining factory precision with on-site assembly to create complete residential structures. In Canada’s diverse climate zones and regulatory environments, these homes have evolved from basic modular units to sophisticated dwellings that meet rigorous building codes and energy efficiency standards.

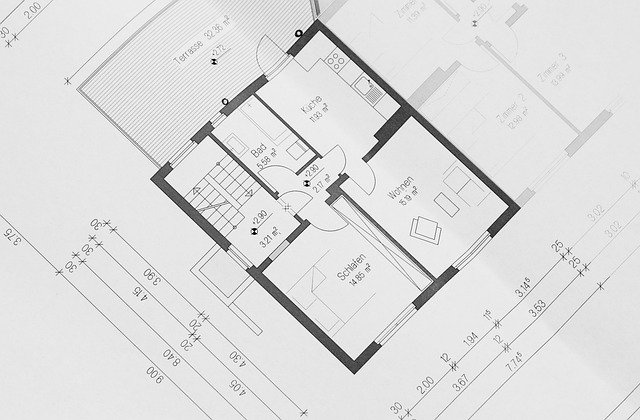

Understanding Prefabricated Home Construction Methods

Prefabricated construction encompasses several distinct approaches, each with unique characteristics. Modular homes consist of complete sections built in controlled factory environments, then transported and assembled on permanent foundations. Panelized systems involve wall panels, floor systems, and roof trusses manufactured off-site and assembled by construction crews. Manufactured homes, built entirely in factories on steel chassis, offer mobility and affordability but face different zoning restrictions. Hybrid approaches combine these methods, allowing customization while maintaining efficiency. Factory construction provides quality control advantages, reducing weather-related delays and material waste while ensuring consistent building standards across all components.

Current Market Trends for Prefabricated Homes in 2026

The Canadian prefabricated housing market continues expanding in 2026, driven by housing affordability challenges, labor shortages in traditional construction, and growing environmental consciousness. Provincial governments increasingly recognize prefabricated homes as viable solutions for affordable housing initiatives. Technological advances in manufacturing enable greater design complexity and energy efficiency integration. Consumer preferences shift toward sustainable building practices, with prefabricated homes offering reduced construction waste and improved thermal performance. Urban infill projects increasingly incorporate modular construction for faster project completion. Rural and remote communities benefit from prefabricated solutions that minimize on-site construction time in challenging climates. Market growth appears strongest in Ontario, British Columbia, Alberta, and Quebec, where housing demand outpaces traditional construction capacity.

Available Design Options and Customization Features

Contemporary prefabricated homes offer extensive design flexibility that challenges outdated perceptions of limited aesthetics. Architectural styles range from modern minimalist to traditional Canadian cottage designs, with exterior finishes including wood siding, brick veneer, stucco, and metal cladding. Interior layouts accommodate open-concept living, multiple bedrooms, and specialized spaces like home offices or workshops. Customization extends to window placement, ceiling heights, flooring materials, cabinetry selections, and fixture choices. Energy-efficient features such as triple-pane windows, enhanced insulation packages, heat recovery ventilation systems, and solar panel integration become increasingly standard. Smart home technology integration allows automated climate control, security systems, and energy monitoring. Manufacturers typically offer base models with upgrade packages, balancing affordability with personalization. Design limitations exist based on transportation requirements, with module widths restricted by highway regulations and overall dimensions affecting shipping logistics.

Construction Timeline and Installation Process

Prefabricated home projects follow distinct phases with compressed timelines compared to traditional construction. Initial design and permitting typically require two to four months, depending on municipal requirements and design complexity. Factory construction of modules or panels takes approximately eight to twelve weeks under controlled conditions. Site preparation, including foundation work, utility connections, and access roads, occurs simultaneously with factory production. Transportation and crane installation generally complete within one to three days for modular homes, though weather and site accessibility affect scheduling. Finishing work, including utility connections, interior completion, and exterior landscaping, adds four to eight weeks. Total project duration from design approval to occupancy typically ranges from five to nine months, significantly faster than twelve to eighteen months for comparable site-built homes. Weather impacts remain minimal since most construction occurs indoors, reducing seasonal delays common in traditional building.

Pricing Breakdown and Provider Comparison

Understanding the complete cost structure helps prospective buyers make informed decisions about prefabricated home investments. Base prices for prefabricated homes in Canada vary significantly based on size, design complexity, and finish quality. Entry-level modular homes start around 150 to 200 dollars per square foot for basic configurations, while custom designs with premium finishes reach 300 to 400 dollars per square foot. These figures exclude land costs, site preparation, foundation work, utility connections, and finishing expenses that add substantially to total investment.

| Provider Type | Base Cost Range (per sq ft) | Typical Features | Additional Considerations |

|---|---|---|---|

| Entry-Level Manufacturers | 150-200 CAD | Standard layouts, basic finishes, limited customization | Foundation and site work separate |

| Mid-Range Builders | 200-280 CAD | Moderate customization, quality finishes, energy upgrades | Delivery within 500 km typically included |

| Premium Custom Builders | 280-400 CAD | Full customization, luxury finishes, advanced systems | Architectural services, extended warranties |

| Manufactured Home Dealers | 100-150 CAD | Factory-built on chassis, limited foundation requirements | Zoning restrictions may apply |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Beyond base construction costs, buyers must budget for land acquisition, site surveys, permits and inspections, foundation construction ranging from 20,000 to 50,000 dollars, utility connections including well and septic systems in rural areas, delivery and crane services, finishing carpentry, appliances, and landscaping. Financing options differ from traditional mortgages, with some lenders treating prefabricated homes differently based on construction method and foundation type. Provincial building codes, municipal zoning regulations, and development charges vary significantly across Canadian jurisdictions, affecting total project costs. Hidden expenses often include engineering requirements for specific sites, upgraded insulation for extreme climate zones, extended delivery costs for remote locations, and warranty coverage variations between manufacturers.

Long-Term Value and Maintenance Considerations

Prefabricated homes built to Canadian building codes on permanent foundations typically appreciate similarly to site-built homes, though market perceptions vary regionally. Resale values depend on construction quality, location, maintenance history, and whether the home meets local building standards. Maintenance requirements mirror traditional homes, with regular inspections of roofing, siding, mechanical systems, and foundations. Energy efficiency advantages often translate to lower operating costs, particularly in models designed for Canadian climate conditions. Insurance availability and rates generally align with conventional homes when properly constructed and permanently installed, though manufactured homes on chassis may face different insurance categories. Warranty coverage varies significantly between manufacturers, with structural warranties ranging from five to fifteen years and component warranties covering specific systems and appliances.

Prefabricated homes offer compelling advantages for Canadian buyers seeking efficient construction, cost predictability, and design flexibility. Success requires thorough research into manufacturers, realistic budgeting for complete project costs, understanding local regulations, and selecting appropriate construction methods for specific needs and locations. As the industry matures and technology advances, prefabricated housing continues establishing itself as a mainstream option within Canada’s residential construction landscape.